In the vibrant industrial landscape of Charlotte, NC, machinery and equipment are vital components of numerous businesses, from manufacturing plants to construction companies. To ensure the longevity and optimal performance of industrial equipment, protecting metal components from wear and stress is crucial. One of the most effective ways to achieve this protection is through expert heat treatment processes. This method is designed to enhance the properties of metals, reduce metal stress, and ensure that equipment performs reliably in demanding environments.

In this blog, we will explore how heat treatment works, its benefits for industrial equipment, and how businesses in Charlotte can rely on expert heat treatment services to protect their valuable machinery. Understanding these processes and their significance will provide insight into how industries in Charlotte can maintain peak performance and durability in their equipment.

The Importance of Metal Stress Relief in Industrial Equipment

Stress relief is a critical concern for businesses in Charlotte, NC, that rely on heavy machinery and industrial equipment. When metal components undergo manufacturing processes such as welding or machining, internal stresses can form due to rapid cooling, thermal gradients, or mechanical deformation. These stresses can lead to warping, cracking, or reduced performance over time, compromising the equipment’s efficiency and safety.

Metal stress relief is a heat treatment process designed to reduce or eliminate these internal stresses. This process typically involves heating the metal to a specific temperature and then allowing it to cool slowly. The goal is to allow the metal to “relax” and reach a more stable state, which prevents future deformation or failure. For industries in Charlotte, this process is essential for ensuring that their equipment is durable and resistant to damage under high-pressure conditions. Without proper stress relief, even the highest-quality machinery can experience premature wear and failure, leading to costly repairs or replacements.

How Heat Treatment Enhances Equipment Durability

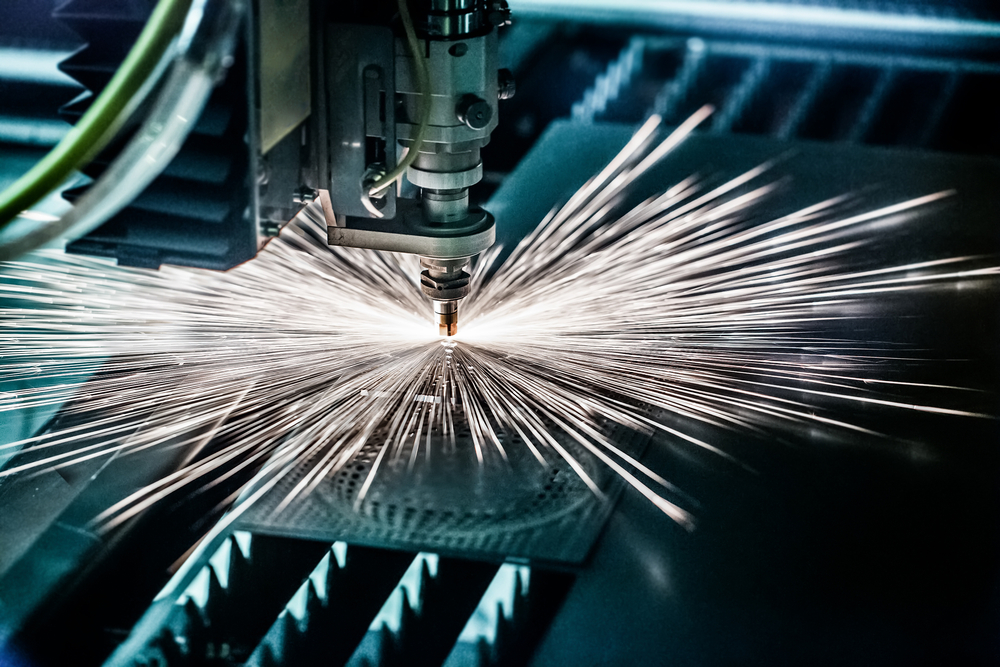

Heat treatment is a broad term that encompasses various processes aimed at altering the physical properties of metals to enhance their performance. For industrial equipment in Charlotte, heat treatment provides several advantages, including improved hardness, toughness, and resistance to fatigue. These properties are essential for equipment used in industries such as construction, manufacturing, and transportation, where components must withstand intense forces and harsh conditions.

One of the most common heat treatment techniques is annealing, which involves heating the metal to a high temperature and then cooling it slowly. This process reduces hardness but increases ductility and toughness, making the metal more resistant to cracking and fracture. This is particularly beneficial for components such as gears, shafts, and other critical parts that experience repetitive stress.

Another key heat treatment method is quenching and tempering, which is used to increase the hardness and strength of metals. In this process, the metal is heated to a high temperature and then rapidly cooled in a medium such as water or oil. Afterward, the metal is reheated to a lower temperature to temper it, balancing hardness with toughness. This is especially important for parts that need to maintain high performance under extreme loads and temperatures.

These heat treatment processes not only increase the strength of metal components but also improve their resistance to corrosion, wear, and fatigue. For industrial equipment in Charlotte, heat-treated components provide superior protection against the demanding conditions they face, extending their lifespan and reducing downtime.

Choosing the Right Heat Treatment Provider in Charlotte, NC

Selecting the right heat treatment provider is crucial for businesses in Charlotte that want to ensure their industrial equipment is properly protected. With so many different heat treatment methods available, it’s important to work with experts who can assess the specific needs of your equipment and recommend the most effective solution.

A reputable heat treatment provider will have extensive experience with various types of metals and industrial applications. They should be able to customize heat treatment processes based on the material composition and desired properties of the metal components. Additionally, a professional provider will adhere to industry standards and safety protocols, ensuring that the treatment is performed accurately and without risk of damaging the equipment.

For industries in Charlotte, partnering with a local heat treatment provider offers the advantage of accessibility and personalized service. Local experts can quickly respond to urgent requests, provide tailored solutions, and deliver consistent results that meet the specific needs of Charlotte’s industrial landscape.

Furthermore, an experienced provider will stay up to date with the latest advancements in heat treatment technologies and techniques, ensuring that their services offer the best protection for your industrial equipment. By investing in professional heat treatment services, businesses in Charlotte can protect their equipment, improve performance, and reduce the risk of costly repairs or replacements.

The Long-Term Benefits of Heat Treatment for Industrial Equipment in Charlotte

The investment in expert heat treatment services can provide long-term benefits for industrial equipment in Charlotte. By ensuring that metal components are properly heat-treated, businesses can avoid the costly consequences of equipment failure and premature wear. Heat treatment enhances the durability and reliability of equipment, leading to fewer repairs, reduced maintenance costs, and extended service life.

Additionally, heat-treated components are more efficient, reducing energy consumption and improving overall productivity. For example, parts that are resistant to wear and fatigue will experience less friction and less need for lubrication, resulting in smoother operation and less downtime. This can lead to significant savings for companies that rely on machinery to meet production demands or maintain operational schedules.

Heat treatment also contributes to the safety of industrial equipment. By reducing the risk of failure due to metal stress, businesses can ensure that their machinery operates safely and predictably. This is particularly important for industries that deal with heavy loads or hazardous environments, where equipment failure could have serious consequences for both personnel and the operation.

In Charlotte, NC, businesses that invest in heat treatment can improve their competitive edge by ensuring that their equipment remains in top condition and able to handle the demands of modern industry. This proactive approach to equipment maintenance will ultimately lead to increased profitability and operational efficiency.

Conclusion

In Charlotte’s dynamic industrial environment, the need to protect valuable equipment from the stresses of daily operations is essential. Heat treatment provides an effective solution for enhancing the durability, strength, and performance of industrial machinery, helping businesses avoid the costs and disruptions associated with equipment failure. By reducing metal stress, improving resistance to wear and fatigue, and enhancing overall component performance, heat treatment plays a pivotal role in ensuring that industrial equipment remains reliable and long-lasting.

For businesses in Charlotte, partnering with expert heat treatment providers ensures that their equipment receives the specialized care it needs to withstand the challenges of industrial use. With the right heat treatment processes in place, companies can safeguard their equipment, reduce maintenance costs, and enhance operational efficiency. As the industrial sector in Charlotte continues to grow, the importance of heat treatment will only increase, making it a crucial investment for businesses looking to protect their equipment and stay ahead in a competitive market.

Need Heat Treatment Services Near You?

Family owned and operated J.F. Heat Treating Inc, is a metal heat treating service company with more than 34 years of experience! Heat treatment is the controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape. We specialize in the through hardening and carbonizing of various steel products in a metallurgical lab. It is our privilege to service and work with the manufacturing and fabrication industries to give the best product service available! Our heat treating services include annealing, aging, quenching and tempering to soften, harden, stress relieve, remove contaminants or provide other material characteristics to parts and components. Contact us today to learn more about what we can do for you!