When it comes to enhancing the durability, strength, and overall performance of metals, the heat treatment process is a critical aspect of manufacturing and industrial services. Metal hardening services in Charlotte have become increasingly essential to various industries, from automotive and aerospace to construction and manufacturing. This guide aims to provide valuable insights into metal hardening services, including their significance, the different methods involved, and how Charlotte businesses can benefit from these services.

The Importance of Metal Hardening

Metal hardening is a process used to increase the strength and wear resistance of metal parts. It is an essential step in the production of durable and long-lasting components that can withstand harsh environments, heavy loads, or continuous wear and tear. By altering the molecular structure of the metal through various heat treatment techniques, metal hardening enhances the material’s overall performance, making it suitable for applications in high-stress industries.

One of the key benefits of metal hardening is its ability to improve the hardness of metals without sacrificing their flexibility or formability. This means that metal parts can become more resistant to deformation and wear, extending their lifespan and reliability. In industries where performance is paramount, such as aerospace and automotive manufacturing, the quality of the materials used is non-negotiable, and metal hardening ensures that parts can meet rigorous standards.

The Heat Treatment Process: What You Need to Know

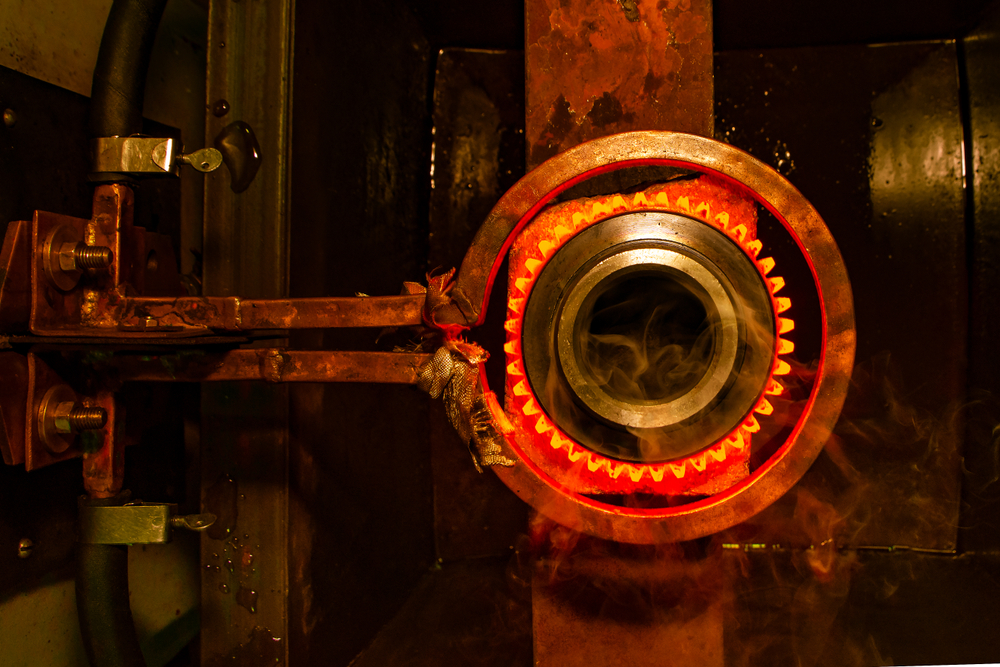

The heat treatment process involves heating and cooling metals under controlled conditions to alter their properties. This process is essential for achieving the desired balance between hardness, strength, and ductility in the finished product. The primary goal is to create a metal that can endure challenging working conditions, such as exposure to extreme temperatures or mechanical stress.

There are several different types of heat treatments used in metal hardening, each with specific purposes and effects on the metal. These include processes like quenching, tempering, annealing, and case hardening. The heat treatment method chosen depends on the type of metal being worked with and the requirements of the final product. In Charlotte, many industrial metalworking companies offer customized metal hardening services to meet the unique needs of businesses in various sectors.

Quenching

Quenching is one of the most common heat treatment methods used in metal hardening. This process involves heating the metal to a high temperature and then rapidly cooling it by immersing it in a quenching medium, such as water, oil, or air. The quick cooling process helps to lock in the metal’s hardened state, making it more resistant to wear and tear. Quenching is typically used for high-carbon steel and alloys that require increased hardness and strength.

Tempering

After quenching, the metal may be too brittle for practical use. To counter this, tempering is often performed. Tempering involves reheating the metal to a lower temperature and then slowly cooling it to relieve internal stresses that may have developed during the quenching process. This results in a more balanced combination of hardness and toughness, making the metal more suitable for various applications.

Annealing

Annealing is another common heat treatment process that involves heating the metal to a specific temperature and then slowly cooling it, usually in a furnace. The purpose of annealing is to soften the metal, improve its ductility, and reduce internal stresses. This process is commonly used for metals like steel, copper, and aluminum to make them easier to work with during further processing.

Case Hardening

Case hardening is a technique used to harden the outer surface of a metal while maintaining a softer, more ductile interior. This process is often used for parts that require a hard outer surface to resist wear, such as gears, shafts, and bearings. Case hardening can be achieved through various methods, including carburizing, nitriding, and induction hardening.

How Metal Hardening Services Benefit Charlotte Businesses

Charlotte, North Carolina, is home to a wide range of industries, including manufacturing, automotive, aerospace, and construction. For businesses in these sectors, the quality and performance of metal parts are crucial for maintaining operational efficiency and competitiveness. Metal hardening services in Charlotte offer several key benefits that can directly impact a business’s bottom line.

Enhanced Durability and Longevity

One of the primary reasons businesses invest in metal hardening services is to enhance the durability and longevity of their products. In industries where metal parts are exposed to extreme conditions, such as high temperatures, heavy loads, or abrasive materials, metal hardening can significantly extend the lifespan of components. By improving the material’s wear resistance, hardness, and overall strength, businesses can reduce the frequency of repairs and replacements, leading to cost savings over time.

Improved Performance in Critical Applications

For businesses in industries such as aerospace or automotive manufacturing, the performance of metal components is non-negotiable. Parts must meet stringent standards to ensure safety, reliability, and functionality. Metal hardening services can help businesses achieve the required performance levels by optimizing the hardness, toughness, and strength of critical components. Whether it’s engine components, turbine blades, or structural elements, metal hardening ensures that parts are up to the task in demanding environments.

Customization for Specific Needs

Metal hardening services in Charlotte offer customization options to meet the unique requirements of various industries. Whether a business needs a specific hardness level, improved wear resistance, or enhanced ductility, metal hardening companies can tailor their services to achieve the desired results. With a range of heat treatment processes available, businesses can select the most suitable method for their needs, ensuring that the finished product performs optimally in its intended application.

Cost Efficiency in the Long Run

While the upfront cost of metal hardening services may seem significant, the long-term benefits often outweigh the initial investment. By improving the durability and performance of metal parts, businesses can reduce downtime, lower maintenance costs, and extend the lifespan of critical components. This ultimately leads to cost savings and a higher return on investment. Additionally, with customized metal hardening services, businesses can avoid the need for costly replacements or repairs, further improving their overall efficiency and profitability.

Finding the Right Metal Hardening Service Provider in Charlotte

When looking for a metal hardening service provider in Charlotte, it’s essential to choose a company with the experience, expertise, and equipment necessary to handle the specific requirements of your business. The quality of metal hardening services can vary significantly between providers, so it’s important to do thorough research before selecting a partner.

Start by assessing the range of heat treatment processes offered by the service provider. Do they specialize in the specific metal or alloy that you need treated? Are they equipped to handle the necessary temperatures and cooling processes required for your components? Additionally, look for providers that offer custom solutions, as your business may have unique needs that require tailored heat treatment services.

It’s also a good idea to check the reputation of the service provider by reading customer reviews, asking for case studies, or seeking recommendations from other businesses in your industry. A reliable provider should have a proven track record of delivering high-quality metal hardening services that meet or exceed customer expectations.

Lastly, consider the provider’s turnaround times and pricing. While it’s essential to prioritize quality, businesses also need to balance cost and speed. A reputable metal hardening service provider will offer competitive pricing and efficient processing times, ensuring that your components are ready when you need them.

Conclusion

Metal hardening is a vital process for businesses in Charlotte that rely on durable, high-performance metal components. Whether your company operates in the automotive, aerospace, manufacturing, or construction sectors, metal hardening services can significantly enhance the durability, strength, and overall performance of your products. By understanding the heat treatment process and its various methods, you can make informed decisions about the best solutions for your business needs. Investing in quality metal hardening services not only improves the reliability of your products but also offers long-term cost savings and a competitive edge in the marketplace.

Need Heat Treatment Services in Gastonia, NC?

Family owned and operated J.F. Heat Treating Inc, is a metal heat treating service company with more than 34 years of experience! Heat treatment is the controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape. We specialize in the through hardening and carbonizing of various steel products in a metallurgical lab. It is our privilege to service and work with the manufacturing and fabrication industries to give the best product service available! Our heat treating services include annealing, aging, quenching and tempering to soften, harden, stress relieve, remove contaminants or provide other material characteristics to parts and components. Contact us today to learn more about what we can do for you!