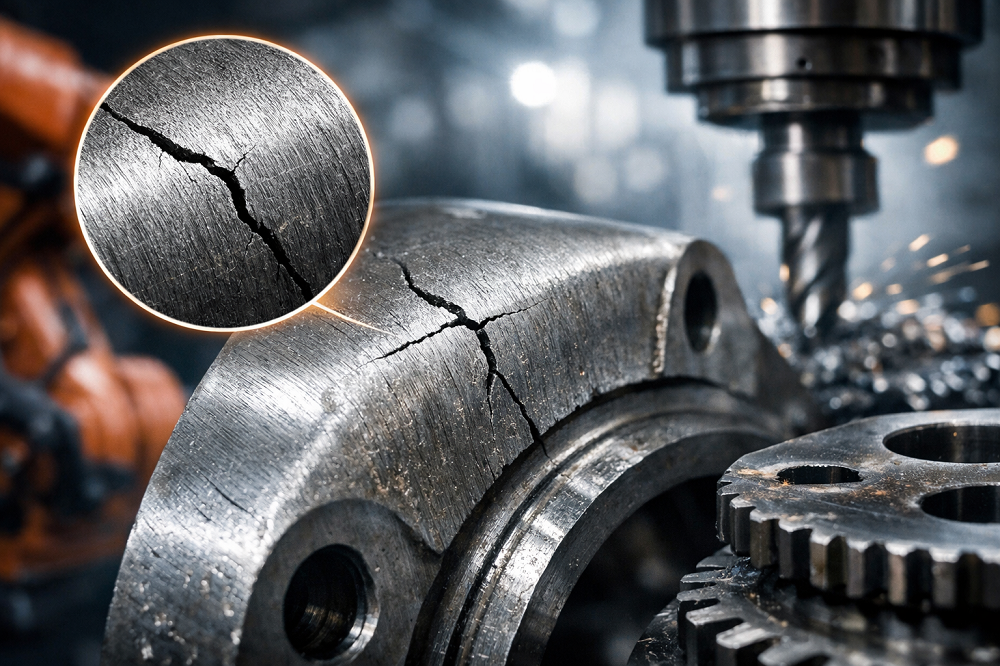

Industrial metal processing facilities in Charlotte, NC rely on precise and durable metal parts to maintain high standards of safety, performance, and longevity. One persistent challenge faced by many operations is the occurrence of microcracks in metal components. These tiny fissures, often invisible to the naked eye, can compromise structural integrity, reduce fatigue resistance, and increase the likelihood of part failure over time. For facilities engaged in metal heat treating and other critical processes, understanding how to prevent microcracks is essential.

This guide explores the origins of microcracks, how they can be prevented during metal heat treating, and best practices that Charlotte-based facilities can adopt to improve reliability and reduce production risks.

Understanding the Formation of Microcracks

Microcracks originate at the microscopic level due to internal stress, temperature gradients, or contamination within the material. These cracks can form during metalworking operations such as casting, forging, or welding, but are most frequently associated with improper or inconsistent heat treating procedures.

In industrial metal processing, metals are often exposed to high-temperature environments followed by rapid cooling. If these stages are not carefully controlled, thermal shock can induce residual stresses that exceed the metal’s tensile strength, resulting in the formation of microcracks. In Charlotte, where industries range from aerospace to automotive and heavy machinery, microcrack formation is not just a technical flaw but a potential operational hazard.

Environmental factors like humidity, oxidation, and chemical exposure can further accelerate crack propagation. For instance, high-carbon steels and alloyed components are more susceptible to cracking if not managed with precision. Detecting and addressing microcracks early is vital to maintaining the integrity of manufactured parts and the safety of final products.

Role of Heat Treating in Microcrack Prevention

Metal heat treating is a cornerstone of industrial metal processing and plays a direct role in either contributing to or preventing microcracks. The process includes heating metals to specific temperatures followed by controlled cooling to alter their microstructure, enhancing hardness, strength, or ductility depending on the desired outcome.

In Charlotte, NC, heat treating facilities must adhere to rigorous quality control protocols to ensure parts meet both performance and durability specifications. One of the most effective ways to reduce microcrack formation during heat treating is through uniform temperature control. Uneven heating or cooling can cause localized stresses that initiate cracks, especially in parts with varying cross-sectional thicknesses.

Stress relief annealing is often used to reduce internal stress before final hardening treatments. Preheating and step-cooling are also essential for minimizing thermal gradients. Facilities must also consider factors such as furnace atmosphere, part loading patterns, and cycle time calibration. Investing in advanced heat treating equipment with better thermal regulation can dramatically reduce the risk of microcracking.

Material Selection and Preparation

Choosing the right material for a specific application is another key factor in avoiding microcracks. Some metals are inherently more prone to cracking due to their composition or microstructure. For example, high-hardness tool steels may offer excellent wear resistance but are vulnerable to cracking if improperly tempered.

In Charlotte’s industrial landscape, engineers must balance material properties with manufacturing constraints. Before initiating any heat treating or fabrication process, materials should be tested for homogeneity, cleanliness, and grain structure consistency. Surface contaminants like oil, rust, or scaling can act as stress concentrators and should be removed via chemical or mechanical cleaning before thermal processing.

Additionally, the geometry of a part influences its risk of developing microcracks. Sharp corners, sudden cross-sectional transitions, or drilled holes can create stress concentrations that initiate cracks during temperature changes. Careful design adjustments, such as adding radii or using fillets, can help distribute stress more evenly across the part.

Advanced Testing and Inspection Techniques

To ensure that metal parts are free from microcracks, Charlotte-based facilities must integrate thorough testing protocols at various stages of production. Traditional inspection methods like visual checks or basic dye penetrant testing may not detect microscopic defects. Instead, more sophisticated techniques should be employed.

Magnetic particle inspection, ultrasonic testing, and eddy current analysis are commonly used to detect subsurface flaws without damaging the part. For high-value or mission-critical components, X-ray and CT scanning can provide a detailed internal view, revealing even the smallest cracks.

Implementing a nondestructive testing (NDT) routine is essential for industries like aerospace or defense, where component failure can have serious consequences. Facilities in Charlotte that incorporate regular inspection cycles into their workflow can identify potential issues early, reprocess flawed components, and prevent costly downstream failures.

Building a Preventive Culture in Charlotte Facilities

Preventing microcracks goes beyond technical processes. It requires a culture of quality and proactive decision-making at every stage of industrial metal processing. For facilities in Charlotte, this means investing in skilled personnel, modern equipment, and continuous training to keep up with evolving industry standards.

Operators and engineers should be trained to recognize early signs of thermal stress, improper heat treating profiles, or material anomalies. Collaboration between design teams and manufacturing units can help reduce design-induced vulnerabilities. Regular audits of process parameters and heat treating cycles can uncover hidden inefficiencies or potential risks.

Partnering with experienced vendors and material suppliers who understand the unique requirements of Charlotte’s industrial sector can also add value. By aligning on quality benchmarks and sharing feedback loops, both upstream and downstream players in the supply chain can contribute to more resilient manufacturing outcomes.

Conclusion

Microcracks are a subtle yet significant threat to the durability and performance of metal parts used in industrial applications. For Charlotte, NC facilities specializing in metal heat treating and industrial metal processing, prevention begins with understanding the root causes, choosing appropriate materials, and implementing tightly controlled thermal treatments.

Advanced testing methods and a strong internal culture of quality control are critical to identifying and eliminating defects before they compromise production. As Charlotte continues to grow as a hub for high-tech manufacturing and industrial innovation, proactive microcrack prevention will be key to maintaining safety, reputation, and long-term operational efficiency.

By combining technological precision with process discipline, Charlotte facilities can ensure the integrity of their metal components and lead the way in setting industry benchmarks for reliability and excellence.

Need Heat Treatment Services Near You?

Family owned and operated J.F. Heat Treating Inc, is a metal heat treating service company with more than 34 years of experience! Heat treatment is the controlled heating and cooling of metals to alter their physical and mechanical properties without changing the product shape. We specialize in the through hardening and carbonizing of various steel products in a metallurgical lab. It is our privilege to service and work with the manufacturing and fabrication industries to give the best product service available! Our heat treating services include annealing, aging, quenching and tempering to soften, harden, stress relieve, remove contaminants or provide other material characteristics to parts and components. Contact us today to learn more about what we can do for you!